Overview:

Wheel weight is used to balance wheel and tire components. Unbalanced tires can adversely affect driving quality and shorten the life of tires, bearings, shock absorbers and other suspension components. Balanced tires help save fuel, extend tire life, and improve safety and comfort.

Composition:

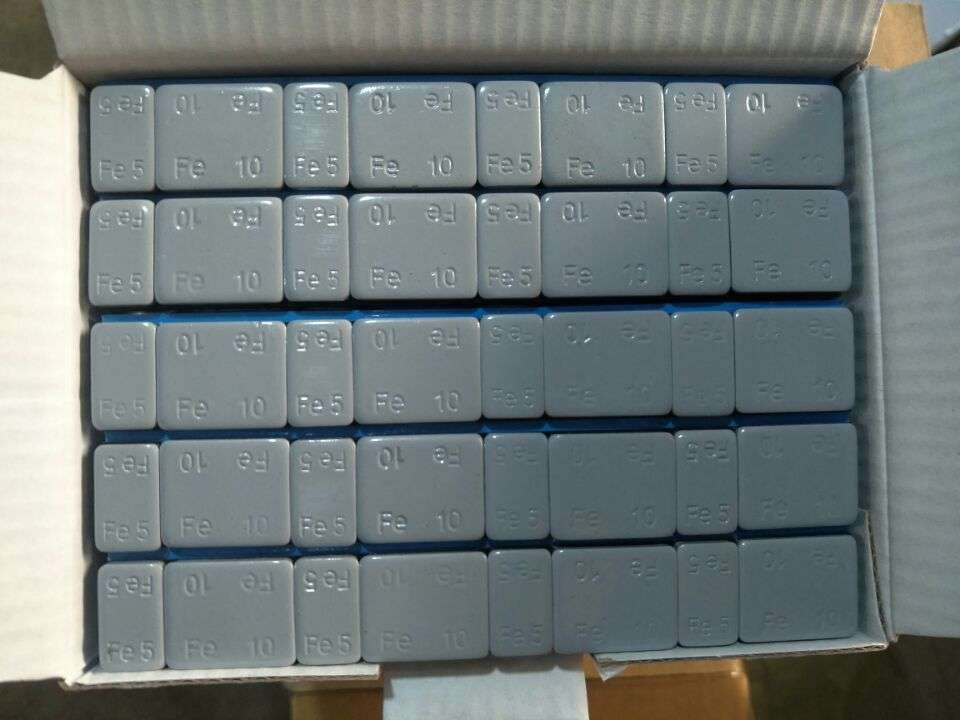

Initially, passenger cars were equipped with steel wheels and the corresponding wheel weight was uncoated lead. Today, alloy wheels are used in modern passenger cars to reduce vehicle weight. When balancing alloy wheels, polymer-coated wheel weights should be used to prevent discoloration and pitting (damage). With efforts to reduce / eliminate lead content in products, polymer-coated steel and zinc have become the only material types allowed for wheel weight.

Types:

Wheel weights come in various sizes and styles and must be properly mounted on the rim to prevent it from moving or falling. Different styles of clips can be used for various types of rims. Self-adhesive weights are also available, which can be mounted on the inner surface of aluminum alloy wheels.

YAQIYA comes with a variety of wheel weights to meet any application of today's passanger vehicles, trucks and motorcycles. They are available in lead, zinc and steel.

How to choose:

The type of wheel weight required depends on the shape of the wheel rim profile. Each vehicle manufacturer can have several different styles of rims on their vehicle. Use the rim gauge to determine the rim profile to identify the type of weight to be used.