1. Find the tire wound and mark the wound inside and outside

2. Remove foreign bodies from the wound

3. Check the Angle and size of the wound inside the tire from the inside out

4. Spray the wound with detergent and scrape it at least 2 times

5. Center the wound and draw the sanding area.The range is about 10mm in diameter greater than the overall crown of the plug

6. Use a low-speed air drill with a carbide steel drill bit to cut the damaged steel wire clockwise from the inside out and from the outside in along the wound damage Angle

7. Use low speed grinding machine with wire brush to clean the polishing area

8. Use a vacuum cleaner, rubber scraps and wire balls

9. Using a screw binder, apply room temperature vulcanizing agent clockwise to the wound

10. Use room temperature curing agent to apply to the polishing area

11. Remove the blue film from the hard and coronal parts of the integral plug and glue it to the crown of the integral plug

12. Apply the room temperature vulcanizing agent on the part of the whole stopper

13. Insert the block stopper into the wound

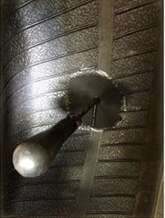

14. Use pliers to clamp the whole plug stem through the wound and pull until the whole plug crown is close to the inside of the tire

15. Use the compacting roller to compacting outward from the center

16. Apply sealant to the edge of the whole plug and the grinding area

17. Excision of the redundant integral pedicle at 2-3mm from the crown