1. The dynamic balance point of the tire is detected by the dynamic balancing machine.

1 Select an appropriate detergent (such as 70% isopropyl alcohol solution) and carefully clean the hub surface with a clean soft cloth to remove impurities and dust on the hub surface.Note: The ambient temperature of the counterweight and hub should be no less than 16 degrees Celsius.

2. After cleaning the hub, put the balance block on the hub, and check whether the curvature of the hub is suitable for placing the balance block. When placing the balance block, the protective film of the back rubber strip is still retained.The radius of the arc of the balance block should be at least parallel to the hub radius.

3. Uncover the protective film of the rubber strip on the back of the balance block and place the balance block on the hub.When the balancing block is placed, a force shall be applied from the center of the balancing block to both ends at a pressure not less than 100 kpa.

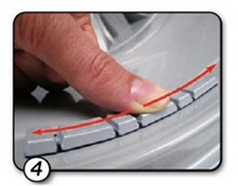

4. After pasting the balance block, continue to press from the middle of the balance block to both sides.The adhesive force of the balance strip reached 80%-90% after about 24 hours, and reached 100% after 72 hours.

Don't look down on the wheel of the dynamic balance block, also don't look down on the small pieces of unremarkable lead, iron, if the wheel dynamic balance is not good will cause abnormal wear tires, will also affect the stability of the vehicle.Especially the front wheels, vibration can be transmitted to the steering wheel through the rotation system, which not only affects the driver's driving, but also leads to loose steering system.