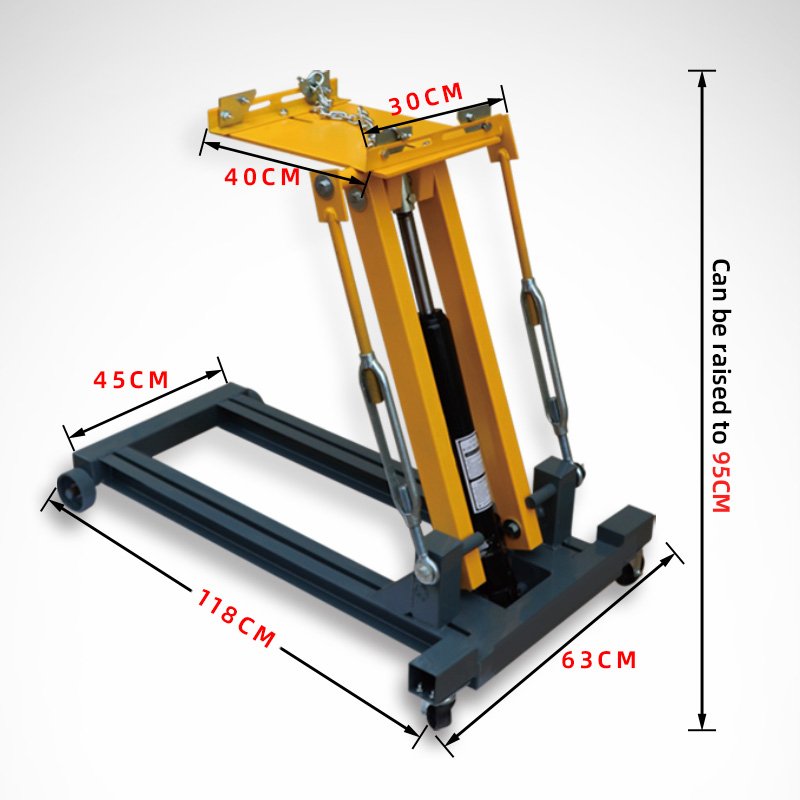

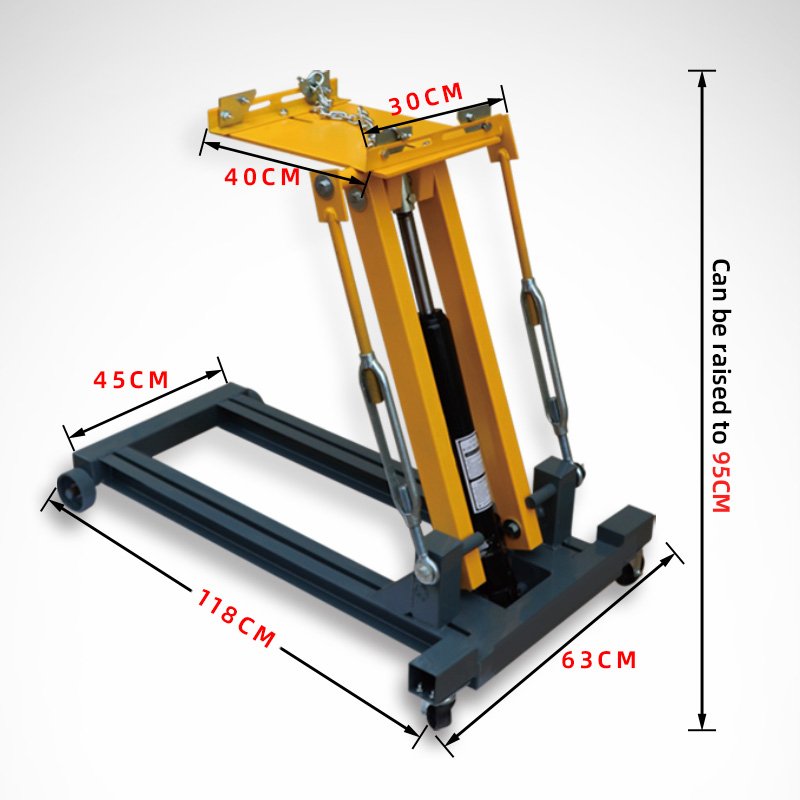

Cheap 2t Vertical Floor Type Low Transmission Gearbox Jack with Adapter

Working Principle

The working principle of the transmission jack is mainly based on two methods: mechanical transmission and hydraulic transmission:

Mechanical transmission:using the principle of lever, screw transmission or gear transmission, a small input force is converted into a large output force, thereby lifting heavy objects.

Hydraulic transmission: through the flow and pressure change of hydraulic oil in the sealing system, the pressure in the hydraulic cylinder is converted into a lifting force, pushing the piston rod to lift the heavy object

Designed for:

Transmission jacks are primarily used to support and lift the transmission components of a car, ensuring stable support during repair and installation.

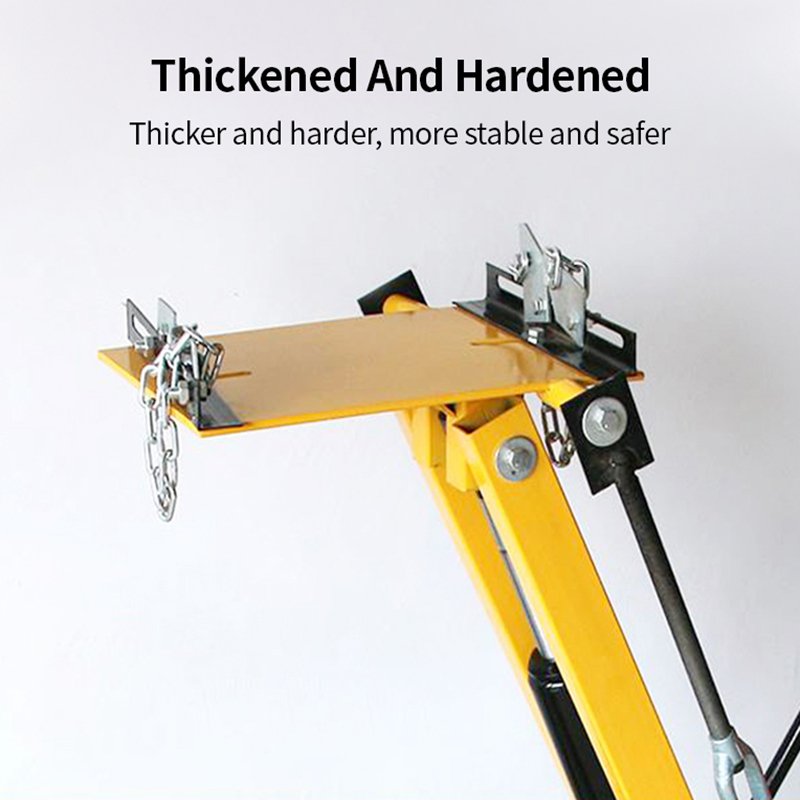

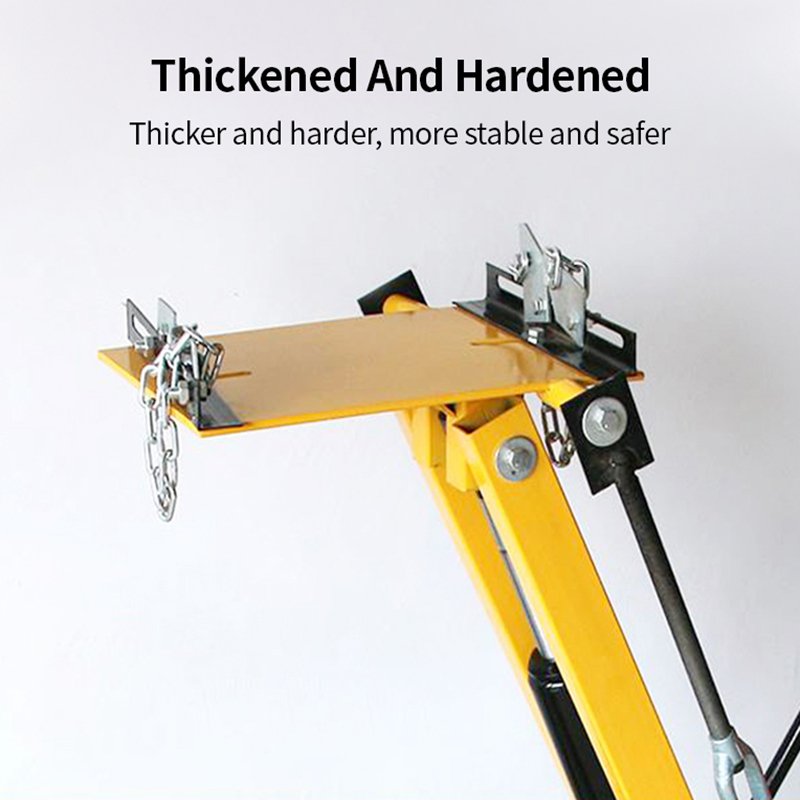

Structural features:

Transmission jacks typically have an adjustable tray or support arm that allows for precise positioning of transmission components. These jacks typically have rollers for easy movement and positioning within the workshop.

Load capacity:

Transmission jacks have different load capacities to suit a variety of vehicles. Common capacities range from a few hundred kilograms to several tons.

Usage scenarios:

It is widely used in automotive repair workshops for replacing gearboxes, clutches, and other heavy transmission components.

Application scenarios

Transmission jacks are widely used in the following fields:

Engineering construction:

used for supporting and lifting bridges and buildings.

Machinery maintenance:

used for lifting and repairing vehicles and equipment.

Heavy object handling:used for handling and installing heavy equipment and materials in factories and warehouses.

Advantages:

Simple operation, safe and reliable.

Can provide greater lifting force, suitable for heavy objects of different weights.

Strong structure and long service life.

Transmission jacks play an important role in modern industry and engineering, and are indispensable lifting and supporting tools.